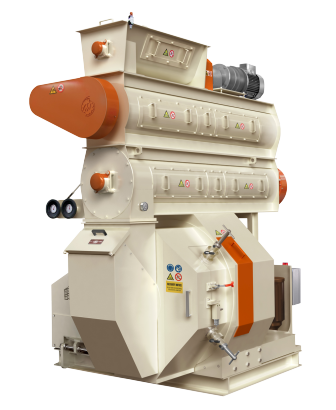

This animal feed machinery, used to create pellets from powdered material, is one of the most important machines in industrial production. It’s usually used to produce animal feed pellets, wood pellets, and fuel pellets for use in a pellet stove. It is mainly used in large-scale commercial production with the features of long working life, high output and low consumption. The work of pressing the wet mash into a pellet is done through the die in the main mill.

La Meccanica pellet presses are simple and solid machines, with high reliability and very low maintenance costs.

The Pellet Mill is composed by:

Screw feeder:

– The variable-pitch feeder is driven by a continuously variable speed hydraulic gear motor

– The whole body of the screw feeder in contact with the feed and the screw feeder shaft are made in stainless steel.

Conditioner:

– The conditioner is driven by its own motor

– The conditioner is entirely stainless steel made including shafts and paddles. To obtain, the best results from adding steam, the paddles of the conditioner shaft are easily adjustable.

Pellet mill Bloc:

– Door: the machine door is entirely stainless steel-made with two knife assemblies

– Magnet: a permanent magnet is fitted in the chute to avoid ferrous metal entering the die

– Overload flap: on the feed conveyor there is an overload flap

– Die holder: The die holder is made of forging steel and has a wear ring.

Die holder front base is stainless steel lined to guarantee longer life

– Basement: the pellet mill is built upon a heavy cast iron base that guarantees the absence from vibration

– Main shaft: The main shaft is mounted on the base by brass bushings. The front of the shaft is a chromed plate for preventing against corrosion

– Drive: the pellet mill is driven by an electric motor via a V-belt transmission. Οι ιμάντες τύπου 5V εγγυώνται τη μετάδοση της ισχύος του κινητήρα με συντελεστή ασφαλείας ίσο με 1,7.

– Shear pin: to protect the pelleting chamber, a shear pin is installed on the rear of the machine

– Lubrication: grazing can be made by the rear of the pellet mill, through the main shaft. In this way, the machine can be lubricated without stopping the motor.

Production Capacities:

Cattle

– Power from 30 kW to 370 kW

– Capacity from 0,15 to 35 ton/h

Poultry

– Power from 30 kW to 370 kW

– Capacity from 0,3 to 45 ton/h

Sawdust

– Power from 45 kW to 400 kW

– Capacity from 400 to 7000 Kg/h

Mineral-Organic Fertilizers

– Power from 75 kW to 355 kW

– Capacity from 1 to 6 ton/h

Organics Fertilizers

– Power from 75 kW to 355 kW

– Capacity from 3 to 10 ton/h