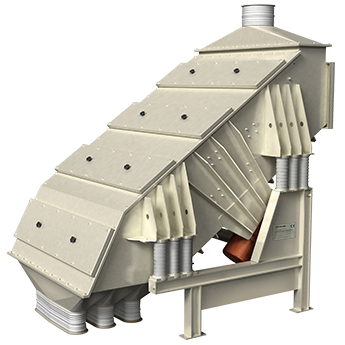

Vibrating sifters are used to remove grit and fine particles from the pellet flow.These are very compact machines, particularly efficient for cleaning pellets or for classifying flours.

In La Meccanica’s vibrating sifter the product in the inlet of the sieve comes levelled on all the width material and is evenly distributed across the screens by means of a static distributor adjustable from the exterior. The mechanical action of the sifter is made by two vibrating motors, positioned below the body of the sieve giving easy access to the counterbalances.

The robust casing is constructed in 3 mm mild steel with lateral reinforcement.

It is mounted on 8 “soft” springs ensuring all dynamic vibration is transferred to the sieving action.

The screens, constructed in stainless steel, are tensionate by means of independent and adjustable springs and attached to two intermediate supports optimizing screen tension. The screens are easy to change from the back of the machine.

The mechanical action of the sifter is made by two vibrating motors, positioned below the body of the sieve giving easy access to the counterbalances.

– Motor Power: 2×0.5kW to 2 x 0,85kW

– Capacity for Pellets: from 5 ton/h to 30ton/h

– Capacity for crumbler: from 4 to 20ton/h

– Screens area: from 1 x 0,82m² to 2 x 1,35m²